|

| Author | Subject: 306 Maxi project |

Chr1sch Chr1sch

Seasoned Pro Location: Worcester Registered: 02 Aug 2014 Posts: 1,025 Status: Offline |

Post #26

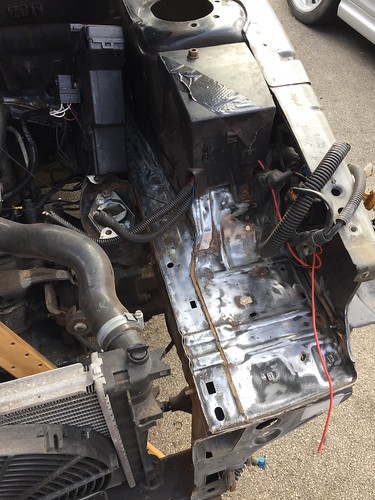

Looks like a great base for a project! |

|

|

|

RallyeRed RallyeRed

Regular Location: Northwich Registered: 03 May 2016 Posts: 353 Status: Offline |

Post #28

Oh and I still need some of those front subframe mounting cups. Any about? |

|

|

|

welshpug! welshpug!

Capt Pedantic Location: Bigend, Wales. Registered: 27 Mar 2007 Posts: 25,817 Status: Offline |

Post #29

abs is standalone yes, will have a power and earth plus ignition and warning light and obd, will sll unbolt/unplug easy________________________________________ need a part number? get on here - http://public.servicebox.peugeot.comBring on the Trumpets. |

|

|

|

gnrlee

Forum Admin gnrlee

Forum AdminLocation: Leeds Registered: 20 Aug 2005 Posts: 8,878 Status: Offline |

Post #30

RallyeRed wrote: Oh and I still need some of those front subframe mounting cups. Any about? either try someone breaking on here to see if they can get one off in tact or take a trip to a scrappy I think they're the same across the range although it does list a slightly different part no for Automatics on Service Box???? ________________________________________ Proud Member of the ASTOR Owners Club |

|

|

|

welshpug! welshpug!

Capt Pedantic Location: Bigend, Wales. Registered: 27 Mar 2007 Posts: 25,817 Status: Offline |

Post #31

auto subframes i believe are spaced down to clear the gearbox.________________________________________ need a part number? get on here - http://public.servicebox.peugeot.comBring on the Trumpets. |

|

|

|

gnrlee

Forum Admin gnrlee

Forum AdminLocation: Leeds Registered: 20 Aug 2005 Posts: 8,878 Status: Offline |

Post #33

________________________________________ Proud Member of the ASTOR Owners Club |

|

|

|

rikky

🦔 rikky

🦔Location: cheshire Registered: 28 Feb 2004 Posts: 26,793 Status: Offline |

Post #34

gnrlee wrote:  not bad.. a typo in every bit you added to the photo  ________________________________________ 306 rallye reproduction decals (full sets/individual decals) | 306 b-pillar textured vinyl weatherstrips306 slam panel esso stickers | 306 yellow / orange / pension fund red side door badges gti6 inlet manifold badges | 306 rear boot badges (p2/p3) winner of Extraction of toys from prams with outstanding vigour award 2009 [source: gti6 owners club] |

|

|

|

RetroPug RetroPug

Seasoned Pro Location: Leicestershire Registered: 15 Jan 2013 Posts: 2,473 Status: Offline |

Post #35

From memory, either horn will work alone if you disconnect the other. I am fairly sure I've tried this, and if I remember correctly some base models only came with one horn, someone else will confirm I'm sure.Can you not connect the battery and test the horns? ________________________________________ 61k miles Ph.1 Diablo '6 Project Thread |

|

|

|

RallyeRed RallyeRed

Regular Location: Northwich Registered: 03 May 2016 Posts: 353 Status: Offline |

Post #36

RetroPug wrote: From memory, either horn will work alone if you disconnect the other. I am fairly sure I've tried this, and if I remember correctly some base models only came with one horn, someone else will confirm I'm sure. Can you not connect the battery and test the horns? Not at the moment I'm afraid - I'm past the point of no return in relocating battery to the boot, so terminals have been snipped and I'll be sorting out a junction box. It's just that particular job is not too high on my priority list, but now it's tricky sorting out which bits are needed as I attempt to sort rust and paint the inner arches. It's odd they have two horns - let's hope I save the right one! Cheers Iain |

|

|

|

welshpug! welshpug!

Capt Pedantic Location: Bigend, Wales. Registered: 27 Mar 2007 Posts: 25,817 Status: Offline |

Post #37

not odd, high and low tone.________________________________________ need a part number? get on here - http://public.servicebox.peugeot.comBring on the Trumpets. |

|

|

|

Day666 Day666

Seasoned Pro Location: Bristol Registered: 20 Apr 2013 Posts: 5,206 Status: Offline |

Post #40

FairPlay Iain ...keep the updates coming & I too locked my car a few years ago & it was delocked but the remote failed  |

|

|

|

gnrlee

Forum Admin gnrlee

Forum AdminLocation: Leeds Registered: 20 Aug 2005 Posts: 8,878 Status: Offline |

Post #41

rikky wrote: not bad.. a typo in every bit you added to the photo    im Dyslexic and was in a rush to get to work you got the jist im Dyslexic and was in a rush to get to work you got the jist  Day666 wrote: FairPlay Iain ...keep the updates coming & I too locked my car a few years ago & it was delocked but the remote failed  sure it wasn't just a key sync issue? how many keys do you have? ________________________________________ Proud Member of the ASTOR Owners Club |

|

|

|

RallyeP6 RallyeP6

Regular Location: West Byfleet Registered: 11 Jul 2013 Posts: 451 Status: Offline |

Post #42

Its good you are doing all the prep work, hopefully you won't need to do anything like that for many years to come. Its all the stuff that no body sees (except on here) that takes the time. Have fun cutting those quarter panels out, no going back from there. |

|

|

|

Twangy Twangy

Senior User Location: heswall Registered: 27 Jun 2014 Posts: 623 Status: Offline |

Post #44

you should be ashamed of yourself pinching my spare panels lol , really moving along with this iain , ,keep up the updates mate,just shows what you can do on limited budget if you do a lot of work yourself________________________________________ wayne mcardle |

|

|

|

RallyeRed RallyeRed

Regular Location: Northwich Registered: 03 May 2016 Posts: 353 Status: Offline |

Post #45

Cheers Wayne - your spares went to a good home  Weather looks decent today, but not so good for next week apparently so will be making hay while the sun shines.. All the time the Impreza is skulking in the luxury of the garage! Got my eye on an EZ up gazebo - can double up as my spray booth too.. Cheers Iain |

|

|

|

gnrlee

Forum Admin gnrlee

Forum AdminLocation: Leeds Registered: 20 Aug 2005 Posts: 8,878 Status: Offline |

Post #46

The rear quarter looks a good fit too  We got the tools and the tallent  At this rate should be done by May! ________________________________________ Proud Member of the ASTOR Owners Club |

|

|

|

prism7guy prism7guy

Seasoned Pro Location: DoncastAAAAARGH Registered: 13 Jan 2008 Posts: 4,637 Status: Offline |

|

|

|

|

Cjwatson27 Cjwatson27

Seasoned Pro Location: Oxford Registered: 17 Sep 2013 Posts: 1,968 Status: Offline |

Post #49

Hi what size and offset are your wheels they fill the arches nicely ________________________________________ Old pugs don't die they just get faster |

|

|

|

RallyeRed RallyeRed

Regular Location: Northwich Registered: 03 May 2016 Posts: 353 Status: Offline |

Post #50

Mate, they're just sitting on a jack. Was supposed to be Pug CB, 8x18 ET10. Turned out to be Ford CB and ET25! Es Cos in other words. So likely I'll be moving them on. Can't go too far wrong with anything circa ET 13 @ 8". Depends on your axle width of course.. |

|

|

|

The Peugeot GTi-6 & Rallye Owners Club - ©2024 all rights reserved.

Please Note: The views and opinions found herein are those of individuals, and not of The Peugeot 306 GTi-6 & Rallye Owners Club or any individuals involved.

No responsibility is taken or assumed for any comments or statements made on, or in relation to, this website. Please see our updated privacy policy.