________________________________________

Super high boost Completed, destroyer of gearboxes and 160mph club

|

| Author | Subject: Stef's Supercharged 205 GTi6 |

superchargedblack1997gti6 superchargedblack1997gti6

Seasoned Pro Location: guildford Registered: 15 Aug 2009 Posts: 2,376 Status: Offline |

Post #76

Great work Stef I bet this little spaceship flies. Credit to you 🤔 |

|

|

|

stef306 stef306

Regular Location: lyme regis Registered: 20 Sep 2009 Posts: 201 Status: Offline |

Post #77

thanks all. Ive now got to learn how drive it again power seems unpredictable sometimes. ________________________________________ 1990 205 gti6 supercharged |

|

|

|

stef306 stef306

Regular Location: lyme regis Registered: 20 Sep 2009 Posts: 201 Status: Offline |

Post #78

Been driving it around for a bit now all seems well UNTILL...........I had developed at tap/knock at the top end - sounded like a common tappet so traced it down to the inlet side started removing parts, removed the timing cover to find that the cover was hold the inlet pulley bolt in! Naturally thought the worst got the bore scope down each cylinder to check if we had kissed any valves. Luckily we hadnt! I had built the engine with a fair amount of clearance. So the inlet pulley had be smacking up and down on its adjustment hence the knock sound i guess, Retimed it all, thoughly cleaned the inner threads and the pulley bolt and a good dose of thread lock and tightened to FT! Torque settings had gone out the window at this point! Turned the key with fear to hear the sound of a smooth and non tapping engine!  : : Anyway here a quick blast im still learning to deal with the power and at the time the tracking was to cock. 4,000rpm seems to be the scary point https://youtu.be/gWgJveDLiRM Stef  ________________________________________ 1990 205 gti6 supercharged |

|

|

|

superchargedblack1997gti6 superchargedblack1997gti6

Seasoned Pro Location: guildford Registered: 15 Aug 2009 Posts: 2,376 Status: Offline |

Post #79

Looks great fun credit to you stef ________________________________________ Super high boost Completed, destroyer of gearboxes and 160mph club |

|

|

|

Day666 Day666

Seasoned Pro Location: Bristol Registered: 20 Apr 2013 Posts: 5,206 Status: Offline |

Post #80

Superb job Stef.....well done m8 ....keep the updates coming on this little rocket  |

|

|

|

stef306 stef306

Regular Location: lyme regis Registered: 20 Sep 2009 Posts: 201 Status: Offline |

Post #81

cheers guys ________________________________________ 1990 205 gti6 supercharged |

|

|

|

tvrfan007 tvrfan007

Seasoned Pro Location: In the garage Registered: 29 May 2005 Posts: 3,488 Status: Offline |

Post #82

Ah same happened to me shortly after a cambelt so i know exactly the noise you describe, i recall it vividly.No damage done in my case either, just had to listen to the awful sound of the pulley shunting the camshaft! ________________________________________ I'm Si btw Night Blue VW Golf GTD Bianca LBSC Rallye - Track/Road Slag Project Thread Sparkling Silver Mini Cooper D - Super Dooper  - (The other half's wheels) - (The other half's wheels) |

|

|

|

stef306 stef306

Regular Location: lyme regis Registered: 20 Sep 2009 Posts: 201 Status: Offline |

Post #83

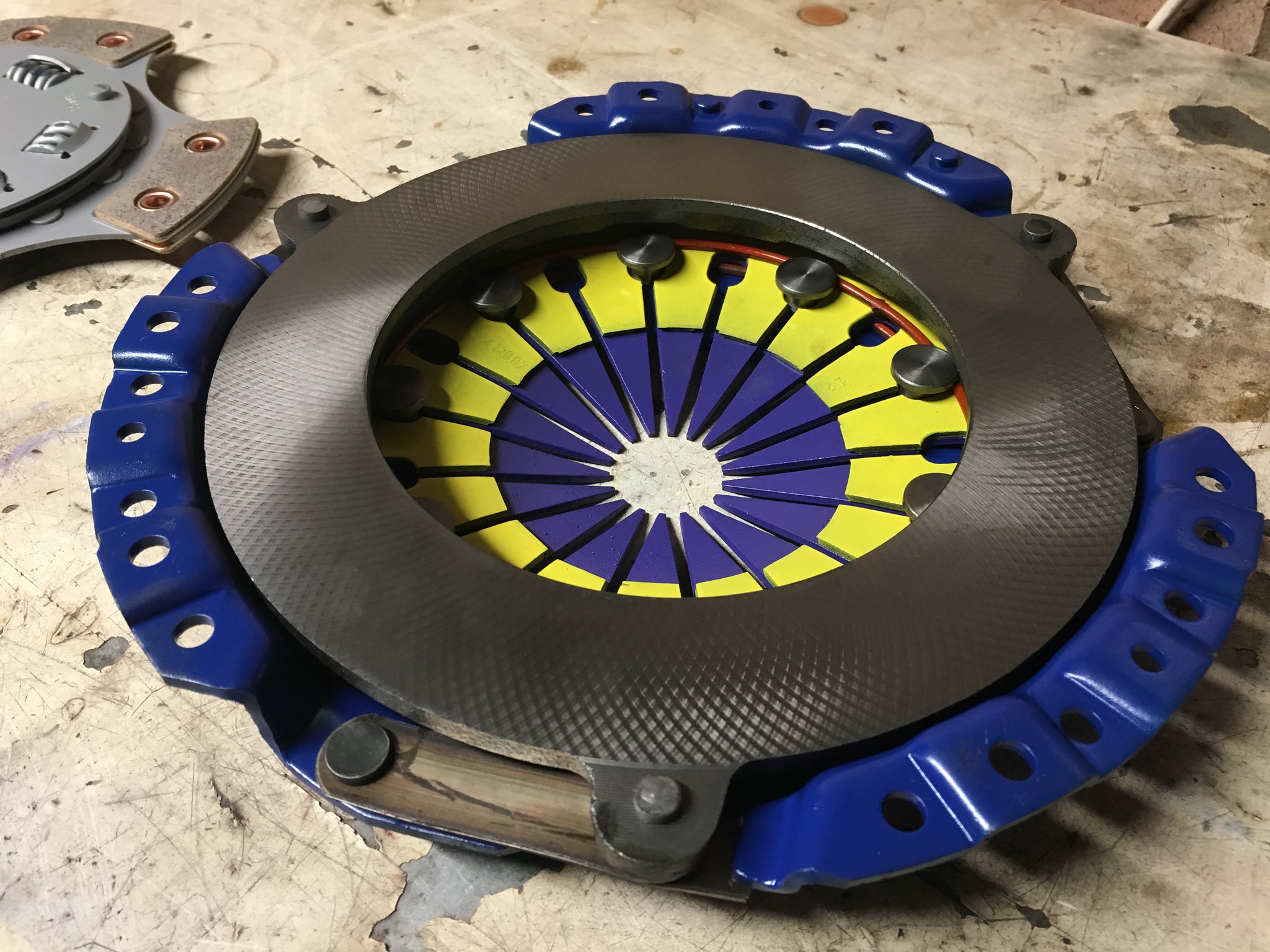

so i broke the diff awhile back just getting around to sort it.   Untitled by stefan golesworthy, on Flickr Untitled by stefan golesworthy, on Flickr Untitled by stefan golesworthy, on Flickr Untitled by stefan golesworthy, on FlickrNaturally the broken fragments got in between each plate and rendered them useless  Phone call to 3j and got some replacement plates. I was able to test the plate break away on the bench before reinstalling it back into the gearbox. For some reason we wasnt able to get the required 75ftlb preload. After abit of research we found that 3j had redesigned some plate and in some cases reducing thickness on some. After shimming the plates we got the required preload. Next we checked the clutch, it had been slipping a few times and after it was removed it from the flywheel it became clear it had been.  Untitled by stefan golesworthy, on Flickr Untitled by stefan golesworthy, on FlickrGot on the phone and arrange another one with abit more effort. After abit of a discussion it was decided the pressure plate was at fault and we opted for a dual diaphragm pressure plate.  Untitled by stefan golesworthy, on Flickr Untitled by stefan golesworthy, on FlickrIm now awaiting on a drivers driveshaft as it has stripped the splines off the tripod bearing  Stef ________________________________________ 1990 205 gti6 supercharged |

|

|

|

stef306 stef306

Regular Location: lyme regis Registered: 20 Sep 2009 Posts: 201 Status: Offline |

Post #84

UpdateWhile i rarely have to drive it or work on it atm, i managed to get some time to finally get the clutch conversion started. Loaded it on the trailer and got it down to the workshop. Within 30 minutes the box was on the floor lol The be3 clutch arm, fork, guides and bearing was removed. https://www.dropbox.com/s/hmwnqy6e0560l6...9.jpg?dl=0 next was to install a be1 pivot ball https://www.dropbox.com/s/7d1k7b23ywe4kh...1.jpg?dl=0 The bolt holes in the gearbox needed to be drill out as they are a stupid m7 thread, once drilled out i helicoiled to a m8 thread. I chose a helicoil as i didnt really trust a alui thread. i offered up the slave which the be1 arm, roughly gauging where the arm would be sat at full reach. I knew the slave mounting pcd holes would not match the gearbox side which was the case. https://www.dropbox.com/s/ftsruzz6z2gk83...3.jpg?dl=0 With needing to fill the holes up i stripped the slave down. It came apart very easy which is one of the reason i chose to use it. Clamped it down to a piece of steel and fired the tig up and filled the holes. https://www.dropbox.com/s/x7mnekbcg219zn...8.jpg?dl=0 https://www.dropbox.com/s/y4s1nuik1jitxf...5.jpg?dl=0 I needed to space the slave from the gearbox so 30mm spacers made from some old inner tie rod made the perfect spacers! HA! https://www.dropbox.com/s/sd7wq03yw429yj...2.jpg?dl=0 With the gearbox side of things finished to a point, i returned my attention to the pedal box. First job was to remove the old pedal box, with a gurt 16v lump and a massive blower in the bay things wasnt going to be straight forward. I refused to remove the engine straight and plain lol We refitted the box then removed the blower and both engine mounts, rad and some pipe work. Then proceeded to pull the engine as far forward as possible. The internet states it cant be done, but with the help of some unorthodox methods it came out with ease. https://www.dropbox.com/s/thr0vfnu5999cz...3.jpg?dl=0 Internet was wrong lol Reminding my self on what i had built over a year ago, I stripped the servo from the pedal box and removed the clutch master. I decided to use a base model servo as they are somewhat smaller. https://www.dropbox.com/s/6yti5y4mrl9gpd...0.jpg?dl=0 https://www.dropbox.com/s/ibv1ez06gizrj9...7.jpg?dl=0 With the pedal box in, i mounted the clutch master and with the engine mounts back on i was happy with the clearance to the engine, considering it was all bench made. https://www.dropbox.com/s/xzc4vsuclavkcm...9.jpg?dl=0 I had intended to use a 406 brake reservoir but in the end i used a bike brake reservoir which seemed to work out ok. https://www.dropbox.com/s/o9u2z926lm9nw9...3.jpg?dl=0 clutch line to the slave was made from some brake pipe and a random 406 front brake hose, i managed to clip it well and followed the 306 pas pipe route. Heres a short video of it working https://www.dropbox.com/s/rtodzkjcgibjgq...2.mp4?dl=0 It all bled easy as gave great results first time around with no alterations needed to the slave spacing. First drive was brilliant with the clutch feeling nice and somewhat lighter! Guess time will tell how reliable is all is. ________________________________________ 1990 205 gti6 supercharged |

|

|

|

stef306 stef306

Regular Location: lyme regis Registered: 20 Sep 2009 Posts: 201 Status: Offline |

Post #85

Update While i rarely have to drive it or work on it atm, i managed to get some time to finally get the clutch conversion started. Loaded it on the trailer and got it down to the workshop. Within 30 minutes the box was on the floor  : :The be3 clutch arm, fork, guides and bearing was removed. https://www.dropbox.com/s/hmwnqy6e0560l6j/IMG_20200601_160309.jpg?dl=0 next was to install a be1 pivot ball https://www.dropbox.com/s/7d1k7b23ywe4khg/IMG_20200601_160931.jpg?dl=0 The bolt holes in the gearbox needed to be drill out as they are a stupid m7 thread, once drilled out i helicoiled to a m8 thread. I chose a helicoil as i didnt really trust a alui thread. i offered up the slave which the be1 arm, roughly gauging where the arm would be sat at full reach. I knew the slave mounting pcd holes would not match the gearbox side which was the case. https://www.dropbox.com/s/ftsruzz6z2gk83x/IMG_20200601_161953.jpg?dl=0 With needing to fill the holes up i stripped the slave down. It came apart very easy which is one of the reason i chose to use it. Clamped it down to a piece of steel and fired the tig up and filled the holes. https://www.dropbox.com/s/x7mnekbcg219zn7/IMG_20200602_130458.jpg?dl=0 https://www.dropbox.com/s/y4s1nuik1jitxfi/IMG_20200602_132405.jpg?dl=0 I needed to space the slave from the gearbox so 30mm spacers made from some old inner tie rod made the perfect spacers! HA! https://www.dropbox.com/s/sd7wq03yw429yjy/IMG_20200602_135552.jpg?dl=0 With the gearbox side of things finished to a point, i returned my attention to the pedal box. First job was to remove the old pedal box, with a gurt 16v lump and a massive blower in the bay things wasnt going to be straight forward. I refused to remove the engine straight and plain  : : We refitted the box then removed the blower and both engine mounts, rad and some pipe work. Then proceeded to pull the engine as far forward as possible. The internet states it cant be done, but with the help of some unorthodox methods it came out with ease. https://www.dropbox.com/s/thr0vfnu5999czz/IMG_20200603_121043.jpg?dl=0 Internet was wrong  : : Reminding my self on what i had built over a year ago, I stripped the servo from the pedal box and removed the clutch master. I decided to use a base model servo as they are somewhat smaller. https://www.dropbox.com/s/6yti5y4mrl9gpdm/IMG_20200530_175230.jpg?dl=0 https://www.dropbox.com/s/ibv1ez06gizrj9i/IMG_20200604_092827.jpg?dl=0 With the pedal box in, i mounted the clutch master and with the engine mounts back on i was happy with the clearance to the engine, considering it was all bench made. https://www.dropbox.com/s/xzc4vsuclavkcm8/IMG_20200604_092339.jpg?dl=0 I had intended to use a 406 brake reservoir but in the end i used a bike brake reservoir which seemed to work out ok. https://www.dropbox.com/s/o9u2z926lm9nw97/IMG_20200606_163223.jpg?dl=0 clutch line to the slave was made from some brake pipe and a random 406 front brake hose, i managed to clip it well and followed the 306 pas pipe route. Heres a short video of it working https://www.dropbox.com/s/rtodzkjcgibjgq8/VID_78720606_151952_932.mp4?dl=0 It all bled easy as gave great results first time around with no alterations needed to the slave spacing. First drive was brilliant with the clutch feeling nice and somewhat lighter! Guess time will tell how reliable is all is. ________________________________________ 1990 205 gti6 supercharged |

|

|

|

stef306 stef306

Regular Location: lyme regis Registered: 20 Sep 2009 Posts: 201 Status: Offline |

Post #86

Has it really been 2020 since i lasted posted in here?! Shameful Car still going, better than ever if im honest. Over the years ive moved the car with the times. Ditched alot of old junk and slowly made the car abit more "serious like" One major improvement was the change of the ecu, We ditched the omex mainly as the car just out grew it. We decided to go with a Maxx ecu race, having seen these in action at a friends place and having hands on with the tuning software and seeing its capabilities i was sold on it. We advanced to fully sequential ignition and fueling, drive by wire throttle, staged methanol injection, engine protection features like oil pressure, temp, battery pretty much every protection its there. Wireless switching for various things via a tablet which also displays data removing the need for gauges. I wired the ecu on its own fresh wiring circuit thanks to a maxx ecu fuse box which is wired straight to the battery and we also removed any unneeded wires within the car. In short term the ecu can do anything we need. Engine has pretty much remained the same but with the ability to control it abit finer now, we added methanol injection to control air temps when on track and to prevent any knock despite a good knock control table. We also gave it the "party pulley" I still stand by that i was pressured into fitting it. With that we fitted some new bosch 550cc injectors. Power wise it made 309whp on a very harsh dyno dynamics but ive neither worried about figures to speak. It drives, its safe, good enough. Heater box was ditched for one of those track heaters as the oem heater never delivered heat to the screen despite many repair attempts. Cage was updated to a safety device cage with a few more bars, with the car getting quicker it made sense. Powder coated in the mandatory red. Brake system is currently going through a major overhaul, still running the nissan skyline calipers up front and gti6 rears we managed to set fire to them at combe one day  : With that ive decided to bin it all, I didnt want to suffer again or experience brake loss at 140mph+ towards avon rise. As most will know im not one for buying stuff off the shelf so i made some brackets and fitted some wilwood 4 pots to the rear, yes the rear : With that ive decided to bin it all, I didnt want to suffer again or experience brake loss at 140mph+ towards avon rise. As most will know im not one for buying stuff off the shelf so i made some brackets and fitted some wilwood 4 pots to the rear, yes the rear  with some modified 207 stub axles in the lathe and some spacers here and there and we now have a vented rear set up. Surprisingly not much weight gain and abut 3mm added track width - win in my eyes, Theyve also got some lovely handbrake levers built with in the caliper to please my mot man. Although it will be backed up by hydraulic. with some modified 207 stub axles in the lathe and some spacers here and there and we now have a vented rear set up. Surprisingly not much weight gain and abut 3mm added track width - win in my eyes, Theyve also got some lovely handbrake levers built with in the caliper to please my mot man. Although it will be backed up by hydraulic.Fronts im still awaiting to arrive but again probably ott but meh. I looked around for awhile and also drew some brackets but in the end decided on some ksport 6 pots and some btcc pads, i plan on doing some serious endos and skids at the local maccy d's so well worth it! There was no question the servo had to be ditched especially to supply fluid to those calipers, a bias pedal box is now in the works. Exhaust is something ive struggled with not only with noise but actually getting it to survive more than a few years. I ripped it all off and made a new system 3" downpipe which traverses into a 2.5 system with a long repackable silencer in the middle feeding a big 8"x24" round rear repackable silencer with a out come of a respectable 92db Since most of this ive really actually enjoyed driving it and has made it drivable again, i secretly fell out of love with it for some time but managed to find the love again, in the summer days its a real hard choice which to drive 205 or evo even climbing over scaffolding. On a serious note i do owe alot of credit to Stephen at p v engineering, even after supplying the ecu, sensors etc the after care support was amazing, always had time to explain and guide me where needed. After supplying him with his jaffer jakes for the year he mapped it with minimal issues even with a broke leg! Photos i havent uploaded to anywhere since the downfall of photobucket and my tightness of willing to pay for it  : :Although i do upload most stuff to instagram so if you want to bore your self photos can be seen there @stef205 Stef  ________________________________________ 1990 205 gti6 supercharged |

|

|

|

stef306 stef306

Regular Location: lyme regis Registered: 20 Sep 2009 Posts: 201 Status: Offline |

Post #87

The last few weeks ive turned my attention to the pedal box, design ive really just winged it but concentrated on the pedal ratio as id rather not be braking with a brick like pedal. 5.6:1 was gained which i hope will be ok. Starting off with .625 cylinder for the fronts and .7 for the rear, Of course this may get changed or swapped at somepoint. I ve also fabbed a brace from the pedal box to the strut brace to try eliminate as much bulkhead flex as possible. Brakes have finally arrive from ksport. First impressions are good, seems like a decent kit. Increased disc size from 285s to 304x28 with their 6 pot caliper. Like a utter child i dashed outside to fit them, despite the rain. They clear lovely behind the td pro 3's, only contact is the dust cap on the bleed nipples so might have to leave them off. Ive got some ex btcc pads to go in which will be more than ill ever need. In search for more camber ive sent the front hubs to our resident machinist at bridgecraft, Unfortanally i need to use 306 hubs for the abs holes for the traction control sensors, did i mention it had that now?  : anyway apon their return the camber should be where its needed. : anyway apon their return the camber should be where its needed. Last year i fitted some 25mm torsion bars so i need to update the front springs to match. Something ive massively under looked for the last few years. Stef  ________________________________________ 1990 205 gti6 supercharged |

|

|

|

Day666 Day666

Seasoned Pro Location: Bristol Registered: 20 Apr 2013 Posts: 5,206 Status: Offline |

Post #88

Hello StrangerHope your well mucker  Great update Stef on your mental 205  I use (IMGUR) which is free to upload pics … Get some pics posted asap please  |

|

|

|

The Peugeot GTi-6 & Rallye Owners Club - ©2024 all rights reserved.

Please Note: The views and opinions found herein are those of individuals, and not of The Peugeot 306 GTi-6 & Rallye Owners Club or any individuals involved.

No responsibility is taken or assumed for any comments or statements made on, or in relation to, this website. Please see our updated privacy policy.